| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

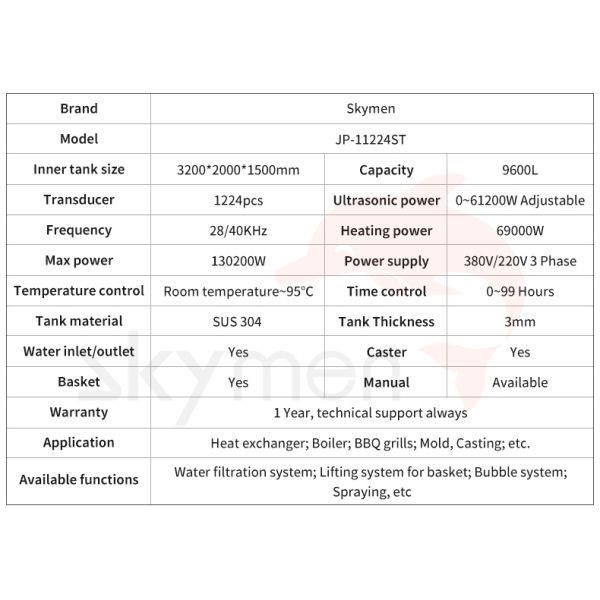

Brand Name : Skymen

Model Number : JTS-11224G

Certification : CE RoHS

Place of Origin : China Mainland

MOQ : 1pcs

Payment Terms : T/T, Western Union, MoneyGram

Supply Ability : 300pcs/month

Delivery Time : nogotiation

Packaging Details : 1pcs/ wooden case

Price : Negotiation

Inner tank size : 3200*2000*1500mm

Material : Stainless steel 304

Power supply : 380V 220V, 50KHz / 60KHz

Timer : 0-99 hours

Heater : 20~95C

ultrasonic power : 61.2KW

Heating power : 36KW

1. Unmatched Precision with Ultrasonic Cavitation

Powerful Micro-Scrubbing Action: Millions of microscopic bubbles form and implode violently, penetrating every crevice to dislodge even the most tenacious, bonded deposits that brushes and jets can't reach.

Surgical-Level Cleaning: Achieve a thorough, deep clean of complex internal geometries, including tiny tubes, intricate fins, and blind passages, without causing abrasion or erosion.

2. Exceptional Gentleness on Delicate Components

Zero Physical Damage: Unlike high-pressure water or mechanical rodding, ultrasonic waves clean through energy, not force. This completely eliminates the risk of tube wall damage, scratching, or surface wear.

Ideal for Fragile Equipment: The ultimate solution for cleaning delicate and precision-engineered heat exchangers, preserving their structural integrity and manufacturer's tolerations.

3. Superior Efficiency & Automation

Clean Entire Bundles Simultaneously: Submerge and clean the entire tube bundle or plate pack at once, slashing cleaning time from hours to minutes compared to tube-by-tube methods.

"Hands-Off" Automated Process: Simply lower the component into the ultrasonic tank and start the cycle. This drastically reduces labor costs, operator skill requirements, and physical strain.

4. Eco-Friendly & Cost-Effective Operation

Drastically Reduce Chemical & Water Use: Ultrasonic action enhances the power of mild, eco-friendly cleaning solutions, eliminating the need for large quantities of harsh, expensive chemicals and high-volume water rinsing.

Minimize Wastewater: The process is contained within a tank, making wastewater collection, treatment, and disposal much simpler, cheaper, and more environmentally responsible.

5. Unparalleled Versatility & Consistency

Universal Compatibility: Effectively clean all common heat exchanger types, including shell & tube, plate, and finned types, regardless of internal complexity.

Guaranteed, Repeatable Results: Every square inch of the submerged component receives the same powerful cleaning energy, ensuring 100% consistent and verifiable cleanliness across the entire unit, every time.

|

|

Heat Exchanger Cleaning Machine For Oil Removal Carbon Deposit Removal Images |